Photo by Christian Lambert on Unsplash

Whilst the focus of capacity improvement at airports often centres on the runway, increasingly we are seeing airports where the ground movement control (GMC) function is also a contributory factor. This is leading airports to consider how to split the GMC role to alleviate capacity constraints, or where the role is already split, to consider a more optimal split that better balances workload between the controllers. Similarly, where airports are expanding and adding new apron areas or runways this also has the potential to change the GMC role and any existing split of responsibilities.

In these situations, a common response is for controllers to set up a Real Time Simulation (RTS) (if they have access to a good tower simulator) and for them to attempt some different configurations of GMC until they find a workable solution. If properly planned and implemented this can be a viable approach. However, often due to the wide range of operational scenarios that need to be tested such an approach can either fail to identify credible options for a GMC split or worse give misleading confidence that a flawed approach is workable. Therefore consideration needs to be given to inter alia:

- Different runway operating directions.

- Different traffic patterns across the operational day (e.g. arrival and departure waves).

- Different geographical splits for the GMC positions.

- Different areas and processes for handover between GMC positions.

- Day, night and visual, low-visibility procedures.

- Different roles for GMC controllers (e.g. one may have other roles such as clearance delivery, or may be a planner).

- When to split the GMC position into two positions by workload/time of day.

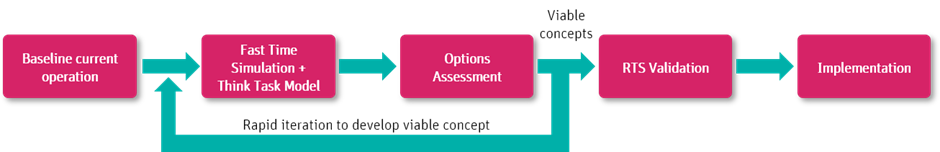

In response to this, here at Think we have developed an approach that allows ANSPs and airport Apron Control units to rapidly prototype, assess and ultimately validate new concepts for the GMC positions across a broad range of operational conditions and modes of operation. It helps reduce unproductive time in the simulator, shortens time from concept idea to implementation and reduces the time needed from valuable ATCO resources:

Fig 1:Overview of the Think GMC assessment process

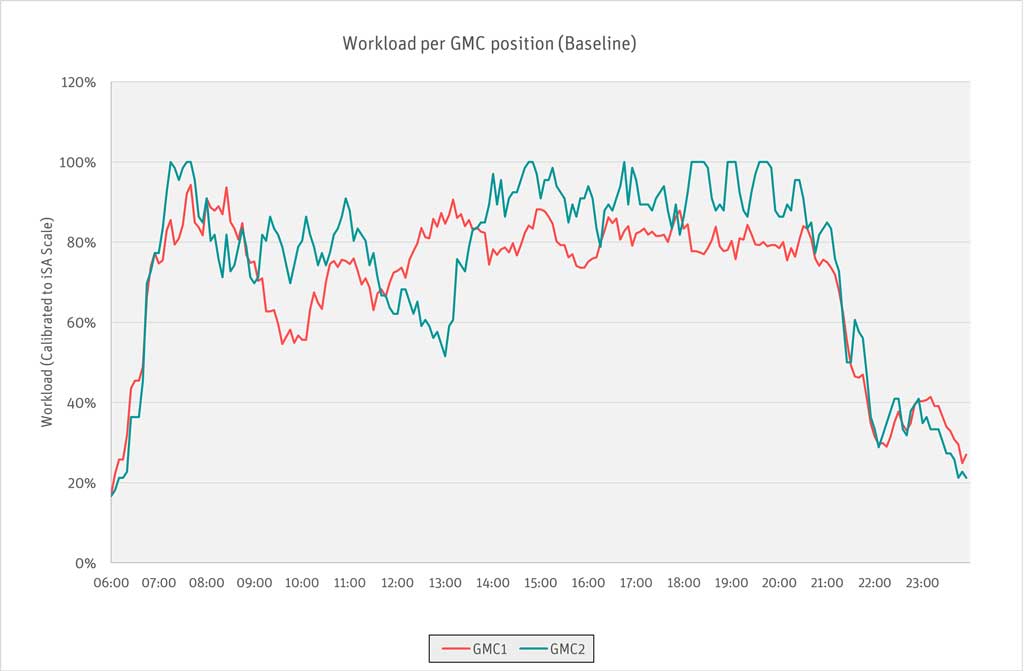

Our approach is predicated on the combined use of airfield Fast Time Simulation (FTS) and a bespoke GMC task timing model that we have developed to represent the activities conducted by the ATCOs together with the typical timings of each. We initially assess the baseline workload of GMC controllers in the present operation operating a representative schedule. To do this we can utilise your own internal workload monitoring tools or we can temporarily deploy our own iSA workload monitor in your operation or tower simulator. We then tailor our task timing model for the specifics of your operation, an activity that can be conducted within only a few days if provided with access to operational staff post-shift. The FTS + timing model is calibrated to the workload levels from the actual operation providing a representative basis for subsequent assessments.

Fig 2: Results from the Think task-timing model

The model can allow the rapid prototyping of alternative configurations of GMC role and geographical split and provides us with an estimate of which permutations are feasible and which would suggest a deleterious effect on workload. Our approach allows for GMC splits and testing of outcomes such that we can quickly narrow down the feasible candidates to a small set very efficiently. These subsets can then be subject to validation in a tower simulator in a much more efficient manner than otherwise possible.

Here at Think our validation specialists can design, manage and analyse the RTS simulator sessions to achieve the greatest set of outputs in the minimum time and ensure that the correct data is collected to provide evidence to support the subsequent operational and safety assessments to underpin the change[3].

Overall, if you are considering how to change or split your GMC positions and are looking for the optimal approach to achieve a safe and efficient operation with balanced levels of ATCO workload our approach can help you.

Authors: Steve Leighton, Airports Director and Elizabet Pavlova, ATM Consultant

Recent Comments